Steel Parts Customized by Professional Casting Factory with CNC Machining for Machine

Parameter

| China Cast Metal Foundry Custom Made Cheap Casting Products | |

| General Products Application/Service Area | Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. |

| Main blank Process for Casting Iron | Sand Casting , Resin Sand Casting, Green Sand Casting, Shell Molding, Automatic Molding, Lost Wax Casting, Lost Foam Molding Casting etc. |

| Blanks Casting Tolerance | CT9-10 for Machine Molding Process, CT8-9 for Shell Molding and Lost Foam Molding Casting Process CT10-11 for Manual Molding Sand casting Process |

| Applicable Material | Ductile Iron, Grey Iron Casting, or as customer request. |

| Casting Blank Size /Dimensions | 2 mm-2000mm / 0.08inch-79inch for casting iron, as per customer requirement |

| Casting Blank Weight | Range from 0.01kg-1000kg for casting iron |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/ Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2, according to customer requirement |

| Applicable Heat Treatment | Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching. |

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting etc. |

| MOQ per batch | For cast iron: 100pcs |

| Lead Time | about 30-45 days for bulk order |

Our Service

* A "bespoke" service to make castings and forgings to customers specific requirements with drawings,samples

* Market-oriented, different grades of products geared to the needs of different customers

* Advance equipment, professional technology and serious inspection procedure to ensure good quality

* In-time delivery will always satisfy customers" needs

* Best after-sale service all the time for a long trade cooperation term

About us

Sino Industry and Trade Co., Ltd. (hereinafter referred to “SITC”) is the sales company of Rizhao Longshan Precision Casting Co., Ltd.

A brief summary of features of SITC is as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. Its only one and a half hours’ drive from our factory to the nearest shipping port-which makes our delivery system more efficient.

5. 40+ years of manufacturing experiences, 15+ years of exporting experience

6. 60% of products sold to overseas customers.

7. 50% of customer base is “Fortune 500 Company”.

8. Carrying out ISO9001 and IATF16949 quality management system.

9. More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers.

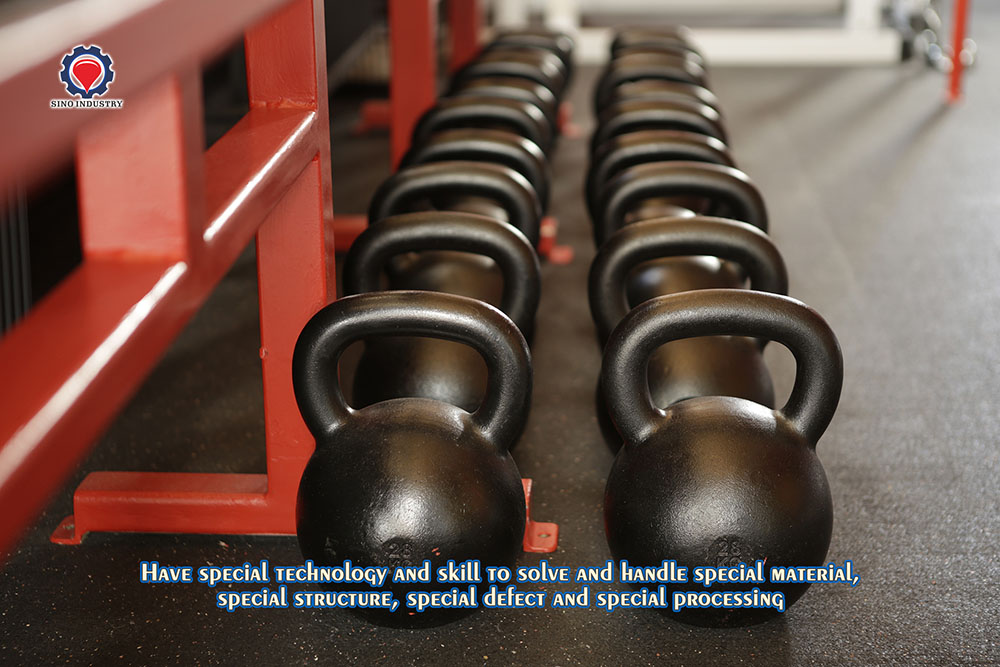

OEM/OEM Casting Service

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

We offer multiple investment casting, sand casting, permanent casting, die casting, investment casting, lost wax casting, gravity casting, low pressure casting, ESR casting, lost foam casting, etc. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.01Kg to 150 tons separately.

Forging Service

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. We offer open die forging, closed die forging and ring forging services. Material can be steel, iron and non-ferrous. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.01Kg to 3,000Kgs

Stamping Service, Welding & Fabrication Service

Welding Frabrication is the fabrication process of metal structures by cutting, bending, then assembling the components together through welding.

We offer manual arc welding ,laser welding and robot welding etc. UT, MPT,RT,PT all are available used for inspection, WPS &PQR (Welding Process Specification& Procedure Qualification Records) before production is available under clients' requirement.

Machining Service

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process.

We have more than 60 sets precision machines incl. CNC center, boring, milling, lathing, etc., and more than 300 inspection instruments incl. 3 sets CMM with grade μm. Repeated tolerance can be maintained as 0.02mm. Meanwhile awarded by certificates ISO9001-2015; IATF16949. We specialize in high precise machining for small-middle-big metal components.

Die casting customization process

1. Provide style and size (2D or 3D) or provide product samples.

2. The customer needs to explain the product processing technology and surface treatment requirements, then we offer the price according to requirement.

3. The die casting department and mold department of the company conduct small batch trial production, and submit the order after confirmation by the customer.

4. Carry out mass production according to the detailed requirements of the order.

5. After the production is completed, we arrange to ship.

Representative casting products

The castings produced by us are widely used in various industries, such as Automobile, Car, Heavy Truck, Light Truck, Commercial Vehicle , Forklift, Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, Marine Hardware, Train, Railway, Petroleum Machinery, Engineering Machinery, Shipbuilding, Power Equipment and other mechanical indusrty. We can produce all kinds of castings according to customer's drawings and customer's requirements, including but not limited to the following:

Steel components, precision steel components, stainless steel components, carbon steel components, alloy steel components, metal components, metal processing, metal stamping, metal punching, metal molding, stamping components, punching components, turning components, molding components, machining, cnc machining, machining components, cnc machining components, cnc components, machining foundry, casting foundry, steel stamping, steel punching, steel turning, steel molding, professional casting, precision casting, precision stamping, precision punching, precision turning, precision molding, casting manufacturer, casting manufactory, custom casting, precision machining, precision casting steel, sand casting, die casting, lost wax casting, investment casting, gravity casting, nonstandard components, auto components, spare components, auto spare components, car spare components, truck spare components, lorry spare components, automotive spare components, automobile spare components, automotive components, automobile components, car components, truck components, lorry components, heavy truck components, heavy-duty truck components, transport truck components, heavy transport vehicle components, vehicle components, forklift components, farm vehicle components, farm truck components, farm machinery components, farm machine components, agricultural vehicle components, agriculture vehicle components, agricultural truck components, agriculture truck components, agricultural machinery components, agriculture machinery components, agricultural machine components, agriculture machine components, combine harvester components, tractor components, trailer components, mining equipment components, mining machinery components, mining machine components, mining truck components, mining vehicle components, industrial components, industry components, equipment components, machinery components, machine components, mechanical components, device components, facility components, engine components, motor components, pump components, pump body, pump shell, pump housing, pump casing, pump cover, water pump, impeller, pump impeller, hydraulic pump components, pump spare components, water pump components, hydraulic spare components, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction, fuel pump, diesel, water pump, vacuum pump, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, valve components, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox components, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, cast iron, cast steel, cast iron components, cast steel components, casting components, iron casting, steel casting, metal casting, cast metal components, sand cast components, sand casting components, cast machine components, cast machinery components, machine spare components, hardware, coupling, marine hardware, precision components, high performance components, high quality components, truck bracket, lorry bracket, engine bracket , motor bracket, steering gear bracket, leaf spring bracket, balanced suspension, suspension system, suspension arm, steering knuckle, vehicle bracket, bumper bracket, exhaust pipe, exhaust pipe manifold, diesel engine, etc.

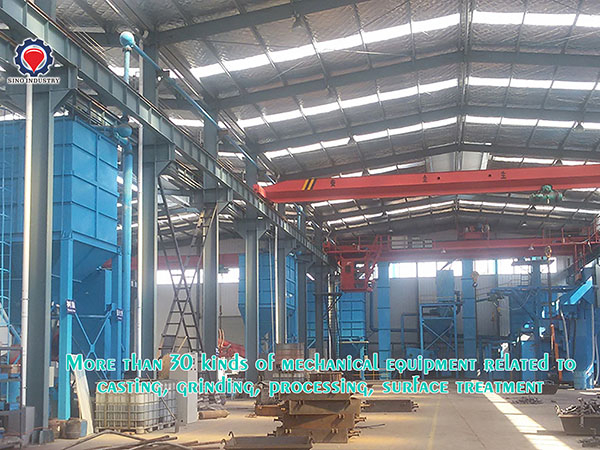

Our advantage

1. Our company has professional engineering R & D department, mold department, stamping department, polishing department, quality inspection department, packaging department, sales department, after-sales department and other departments.

2. Our company has advanced and perfect precision casting supporting equipment, German spectrum analyzer and test equipment, metallographic microscope, 1200KN press and mechanical performance test equipment, multi-element analyzer, Richter hardness tester, helium pressure leak detector and other test equipment.

3. We can design molds and produce casting products according to customers' requirements, samples and drawings, and make all kinds of rough parts and finished parts.

4. we have matching production equipment, including rapid high-frequency melting furnace, resistance melting furnace, horizontal pouring machine, turnover pouring machine, low-pressure casting machine, quenching furnace, curing furnace, shot blasting machine, sand blasting machine, laser cutting machine, laser welding machine, ion cutting machine, CNC machining center, milling machine and other equipment.

Industry Service

We can play a professional value in any industry that needs steel parts. We provide high quality parts for more than 30 industries and the main markets.

MINING INDUSTRY

We supply High-Quality casting parts and forging parts for mining industry, these parts are used for drilling, blasting, digging, transporting, crushing and refining. All of components can withstand harsh and abusive work environments.

These components can be roller levers, pallets, hammers, chain links, adapters, sleeves etc.

CONSTRUCTION MACHINERY

Wear resistant castings and high strength forgings are very common in construction machinery. They help machines to build facilities, transport materials, landfill, and maintain roads.

Maple provides reliable long life parts for customers to finish projects and cost down.

● Track Links

● Lifting Eyes

● Bearing Covers

● Tooth Blocks

● Track shoes

● Mounting Brackets

● Bucket Teeth

● Clamping

● Quick Joint

● Sprockets

● Side Plates

● Beam connectors

● Trencher Tooth

● Coupling

OIL & GAS INDUSTRY

Maple's castings are widely used in the exploration, pumping, transportation filtering and refining of both oil and gas. We have rich experience in manufacturing the parts with highest degree of quality, durability and corrosion resistance. The components are made from tough, high specification materials, often involving high levels of product verification and testing.

We can cast parts with complex internal structure, special material and high performance.

● Valve Components

● Impellers

● Pump Bodies

● Flanges

● Drilling Components

● Burner Parts

● Bottom Plate

● Crank Arm

● Compressor Components

● Instrument accessories

● Blowout Protector

● Fittings/Couplings

● Rod Locks

● Jack Parts

AGRICULTURAL INDUSTRY

Agriculture is the oldest industry in the world. Maple utilizes investment casting to manufacture parts and components with long life cycles and high durability for tough agricultural applications.

RAIL & TRANSIT

Rail & transit industry has large demands of high quality safe cast components. Maple provided steel parts for rail rolling stock, maintenance equipment, railway infrastructure, trucks and wagons.

FOOD PROCESSING INDUSTRY

MEDICAL EQUIPMENT

HYDRAULIC CYLINDER

FORESTRY & LOGGING

FAQ

We're a genuine factory, we have our own casting foundry and machining factory over 40 years. Sino Industry and Trade Company is the sales company of Rizhao Longshan Precision Casting Co., Ltd.

Yes, we are a professional metal fabrication factory with 40 experiences to make custom products according to clients' drawings.

Yes, we will not release your design to third party unless with your written permission.

Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Generally in 1-2 weeks.

In general, the lead time is about 30~45 days for opening new moulds and mass production.

The company can accept a range of formats for drawings, but the main ones are detailed as below: 2-D, PDF, AND TIFF, 3-D, STL, IGES, STEP, Solidworks, etc.

Welcome and anytime.